SILOS ARE JUST THE BEGINNING

CONSISTENT, EFFICIENT, AND GREEN

At Greenwood Silo, silos are just one part of the equation to your vertical storage needs. In addition to refurbished silos, Greenwood Silo also offers affiliated kits, products and services that help farmers grow. With the suite of tools and innovations available from Greenwood Silo farmers are assured that they are getting the best possible expertise, equipment and tools to provide premium forage for their livestock year-round.

- Harvestore Refurbished Sealed Silos

- Agricultural and industrial applications

- Full-service turnkey planning for entire systems

- Site planning and preparation

- Foundation construction

- Silo installation

- Pressure and vacuum testing

- Unloader installation

- Training and post-sale support

YEAR-ROUND FEED SUPPLY

A properly sealed and maintained bottom unloading silo renders numerous positive results for your operation and helps achieve a year-round feed supply.

Here's How:

- In dry spells animals graze too close to the ground, which stunts the regrowth of grasslands.

- When it is wet, the animals can easily trample and damage grasslands.

- During the winter fresh grass isn’t available due to freezing and snow cover

- In the summer heat, supplemental feed can be supplied from the silo, so that grazing can take place during the cool of night.

- Animals fed a finely chopped wilted forage will consume more high energy nutritional dry matter into their system.

- In perfect conditions, grazing animals do not require any supplementary feed, but ideal grazing conditions are not permanent.

- Graze your animals and harvest your crop at its optimum maturity.

- Remove as little as a few buckets of feed up to multiple tons per day.

- Eliminate the feast and famine effect on the seasonal food supply chain.

GRAIN BINS

Greenwood Silo is extremely pleased to offer Sukup and its lines of grain bins, grain dryers and other grain and material handling equipment.

GREENLINE BOTTOM UNLOADERS

Greenline unloaders are extremely durable, longer lasting and more efficient than standard unloaders.

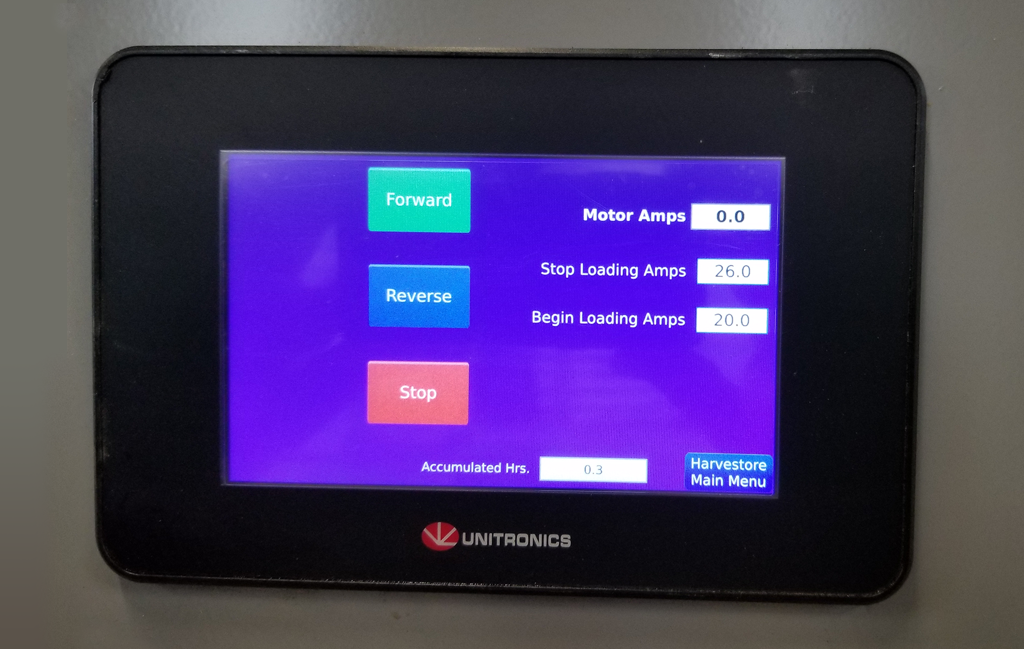

GREENLINE DRIVES

Greenline Drives were developed due to the inadequacies in traditional hard-start motors. The drives feature soft-start, variable speed capabilities. FIELDLINE FORAGE BLOWER

Easily the best blower on the market, the Fieldline Forage Blower is manufactured in USA. The Fieldline blower is a heavy-duty piece of equipment that gets the job done efficiently.

FIELDLINE COMBINATION FORAGE CART

Fieldline’s Combination Forage Cart features a hydraulic rear unload and hydraulic tailgate for fast and efficient unloading. The hydraulics and beaters are operated from inside your tractor’s cab.CIRCLE C GOLDEN EAGLE WHEEL RAKE

The Golden Eagle Wheel Rake is specifically designed to decrease drying time and to tackle the challenges of raking or merging hay and forage crops.

We specialize in quality rebuilt structures. We don’t simply move a worn-out silo from one location to another.

As we dismantle the used silo, we handle and stack the sheets carefully. Then all of the sheets are brought to our facility and inspected so that only quality sheets that have passed the test of time are rebuilt into your silo. We keep all the sheets from one silo together, except for the defective sheets that we replace with good ones from our stock. One of the last steps before we bring the sheets to your farm is acid washing to remove grime and unsightly streaks. As we assemble the silo at your farm, the last step before we raise the silo to install a new ring is Citro treatment. This removes extra sealer and other debris from the sheets, and gives them a shine. No one would guess that you paid less than new price for your refurbished Harvestore*! Not just moved… Rejuvenated!